With sublime printing machines which are available at the plant, and with its limitless color and pattern option, company, primarily the trademarks and current trends, is capable of making finished good production over all polyester and nylon grounds, including recycled fabrics which are environment- friendly and which are sensitive to zero- waste projects. Reactive digital printing machine has reactive direct digital printing capacity by 10.000 me/ day over cotton, viscose and linen groups.

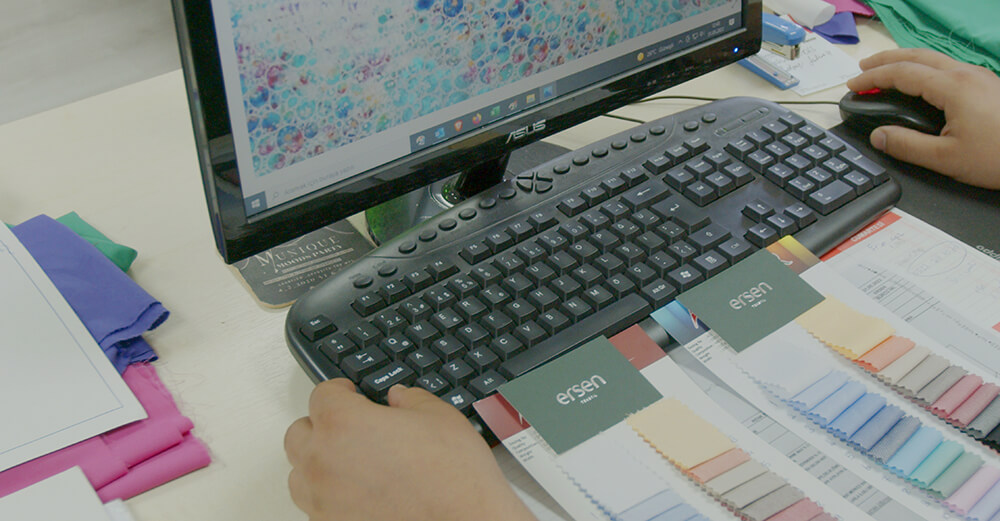

Ersen Tekstil; primarily cotton, polyester and viscose – based qualities, with its fabric collection which is continuously renewed according to knitting, domestic and import weaving season and trends, renders service with the principle of introducing the best quality, with most appropriate price and delivery terms to world-known trademarks.

Ersen Tekstil; starting from use of natural resources and raw material stage for the product and services, so as to include production, use, consumption, recycle stages, in all lifecycle processes up to final disposal stage, hereby aims to avoid the deterioration of ecosystem, and to alleviate negative effects on environment, human, health, climate and natural life for the consumption of natural resources.

We introduce new products into our product range by our RESEARCH AND DEVELOPMENT works and we meet developing expectations and needs in our sector, and we also follow up the process of improvement, protection and development of all environmental values which create the environment of future generations without endangering the existence and quality of sources which are vitally necessary for future generations.

With its approach which is open to improvement, Ersen Tekstil hereby attaches importance to and supports research and development works which increase the efficiency by getting integrated with creativity and which is conducted in success- oriented basis with measurable results.

In our Laboratory, all steps starting from color analysis up to the end of dyeing are managed under computerized environment by our expert staff.

Color Works:

In order to reach the color requested, we find the paint rates of the color by using Spectro machine and later on we produce these colors in our automating pipetting machine by zero – touch. Accordingly, we introduce our customer the advantage to see the exact copy of the ordered color beforehand which would occur after dyeing and drying processes.

Dye Charging ( Lot ) Test :

This is the application of processes on your order by applying it over the sample of order with same water, dye and chemical rates prior to applying it on the real order.

PH Test :

The test which enables us to determine the quality of chemical, of which the PH is measured, where 10% solution of the chemical is prepared.

Solid substance Test:

It is a test made by solid substance determination device and made manually where rate of humidity is measured in solid substances and the compliance of the quality of the solid substance is found.

Hardness Test:

It is the process in which the hardness of water is measured and its compliance is determined by taking 50 ml. from the water sample accompanied with various different procedures.

Physical Tests:

It includes tests which may be applied in our advanced physics laboratories on samples received after production so as to enable the orders to comply with particular properties ( shrinkage, Saliva fastness, perspiration fastness, water fastness, multi- fiber, etc.) in line with our customers’ requests thereof.

Ersen tekstil company is located at Barakfakih organized industrial zone over a 11.000 m2 – area including modern machine park, with its indoor area of 7.500 m², and is capable of dyeing % 100 Pes, % 100 Cotton , % Viscose and their qualities either with lycra or not by using Pipe, Drum , Mcs and Pad jig type dyeing machines. Having a daily dyeing capacity of 35 ton/ day, our company acquires a wide range of product for various sectors such as men, women underwear, outerwear, sportswear , shirt, tie, bag , upholstery, home textile.

Besides having the advantage of 200.000 meter/ day work capacity in finishing machines, we can make edge- cutting, edge ironing as well. In addition, we introduce added values into our products by our top-stich, sanforizing, calender, cold beaching and teasel raising machines .

All dyeing works are processed according to the relevant procedure and all stages thereafter are monitored and measured by our automation systems which are prepared by special software programs at our plant.

With our wide color scale, our technical infrastructure which can create all colors requested by the customers render the best service to its customers by using natural and healthy paints .

Ersen Tekstil works 50, 100, 200, 500, 600- dyeing boilers according to the volume of the order and do not compromise from quality and standards